Kanban 4.0

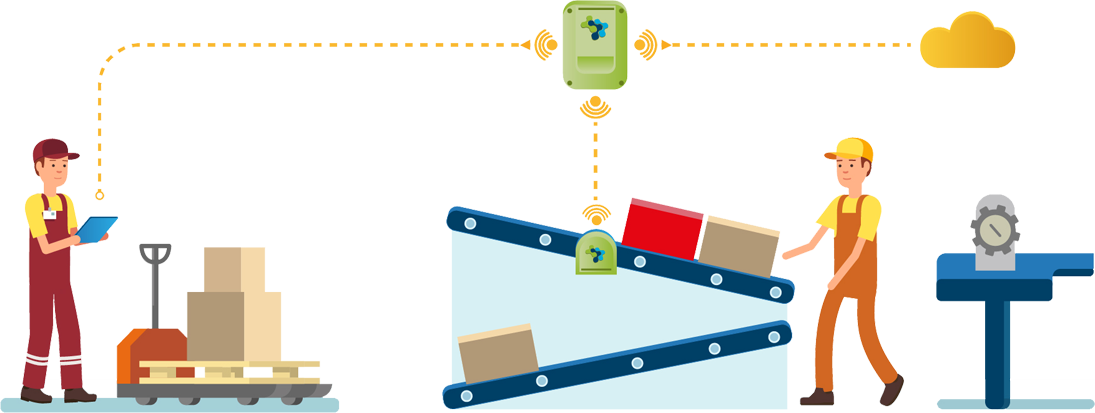

Kanban 4.0® is Maccion’s automated internal logistics management system.

Our customers use Kanban 4.0 ® to adjust their production and improve material sourcing efficiency.

The results of the implementations in different productive plants have been:

The functionalities of Kanban 4.0 ®

Social Contact