Traceability and logistics management throughout the supply chain with RFID technology

11/01/2023

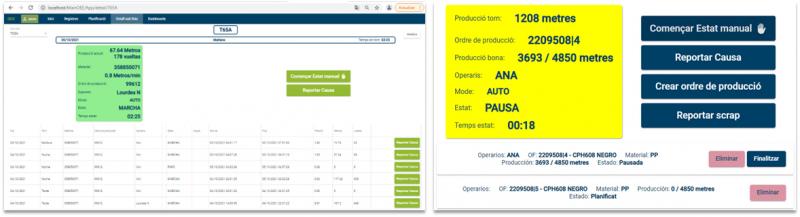

Señor is a tailor-made tailoring company with a manufacturing process very adjusted to the needs of its customers. The items that make up an order follow highly variable production routes between warehouses and workshops. Sometimes, the same orders can be broken down into external processes and logistics traceability becomes a key issue. Maccion has developed a tracking and traceability platform based on a combination of barcode scanning and RFID tags to optimize order reception and dispatch processes. You can now monitor in real time the status and location of each operation.

– Core Technology: Iot

– Associated technologies: Cloud, connectivity, AI, Iot, Big Data, Systems Integration.

MAIN CHALLENGE TO BE SOLVED:

The outsourcing of certain operations and the variability of the items to be considered. The solution must facilitate data entry in a very user-friendly way and allow searching and filtering with data from the different management systems that integrate the stores, warehouses and workshops.

RESULTS / BENEFITS OBTAINED:

– Reduction of the time required to enter system parameters.

– Real time inquiries such as stock availability or estimated delivery time of items.

Social Contact